There are few sectors where efficiency and profitability are so closely linked as manufacturing. But there’s a tactic that can significantly improve the bottom line. Deploying a unified communications solution provides measurable improvements that relieve bottlenecks and fuel productivity across the enterprise, from the front office to the back office, a recent survey of RingCentral customers shows.

Get the stats

As with other sectors, the health crisis didn’t spare most manufacturing companies. But steady consumer demands also meant that many such organizations saw lower declines than other industries during the crisis. While manufacturing GDP dipped 6.3% in 2020, Deloitte forecasts growth of 3.5% this year—and reports that 63% of executives are optimistic about business recovery in the coming months.

Consumer demand puts pressure on manufacturing firms

But while consumer demand may be on the upswing, the pressure is on for firms to scale up innovation and unleash greater efficiencies in order to control costs and mitigate challenges to global supply chains, including trade wars and labor disruptions (which all lead to supply disruption and the need for closer communication and collaboration). For 20% of manufacturing executives, managing productivity is currently the number one challenge, according to a recent outlook report. Meanwhile, just one in five leaders is confident in their organization’s ability to quickly respond to shifts in sourcing, manufacturing, and distribution as the need arises.

Digital transformation and embracing Industry 4.0 are just one of the ways manufacturers are meeting these imperatives. To reduce costs and tariffs, speed time to market, and improve organizational resiliency, many companies are also bringing production closer to home, bringing online new facilities that are in closer physical proximity to end users.

RingCentral can be a powerful partner for manufacturers

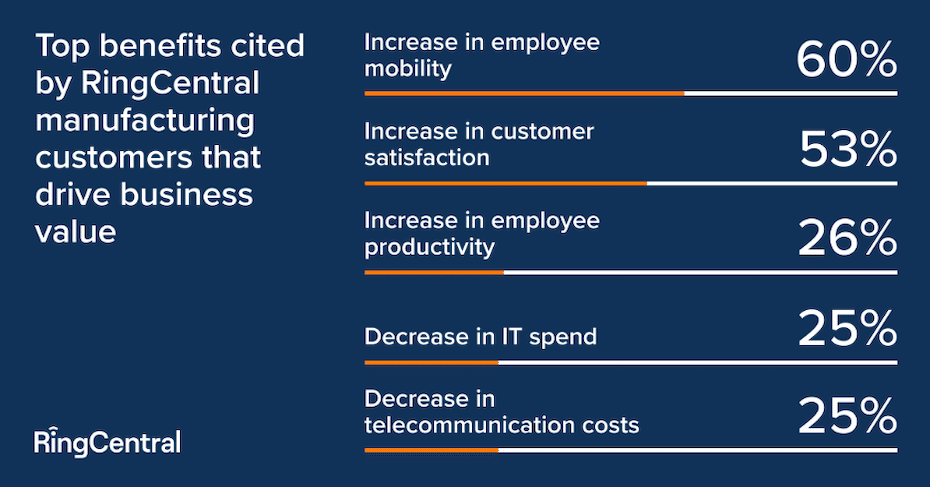

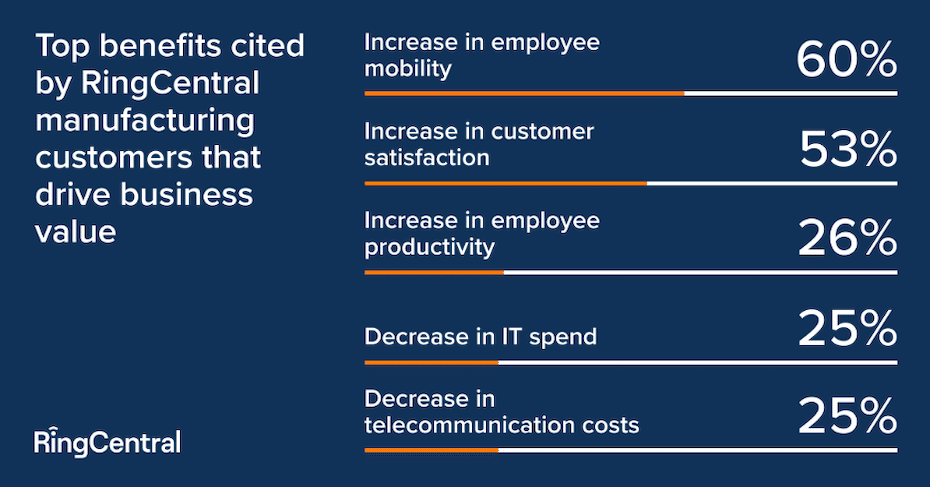

Data from our recent customer success metrics survey highlight how RingCentral can be a powerful partner for manufacturers in this fast-paced, competitive landscape:

60% improvement in employee mobility

Manufacturing has never been a strictly desk-based job, and the challenge of connecting staff across multiple plants and offices often creates efficiency bottlenecks that prevent sales, production, as well as engineering and support teams from working as one in real time. To maintain production momentum, employees across the business require tools that enable seamless, real-time communication from the plant floor, from the road—or from anywhere.

RingCentral customers report a 60% improvement in employees’ ability to access and use digital communication tools from any location. This promotes the flow and visibility of information, making it easier to drive efficiency, and maintaining critical communications between production facilities and the front office.

26% increase in employee productivity

From lockdowns and the need for social distancing and increased safety measures on plant and office floors, to remote work arrangements for back-office workers, the health crisis has strained productivity for many manufacturers. Ironically, this comes at a time when process automation and the internet of things were supposed to help firms pick up the pace.

Deploying a unified communications solution is a significant way firms are bridging the gaps between this promise and their current reality. RingCentral customers reported a significant 26% increase in employee productivity due to improved access to information and resources, the need to use fewer apps to collaborate effectively on any device, and the seamless integration of our messaging, video, and phone solution with other critical workflows and applications.

Jocelyn Vallieres, Sr Director Value Acceleration, RingCentral, comments:

Frankly, I cannot think of any enterprise that would not benefit from 26% more employee productivity. Employees can perform their tasks much more effectively now, whether hoping to get access to critical information, or subject matter experts, one can instantly see who is available to help whether located nearby or somewhere else across the globe. The beauty of implementing RingCentral’s cloud solution is that companies can keep their previous capital (Cap-ex) for other initiatives and still generate the benefits uncovered by the survey.

25% reduction in IT spend, telecom and hardware costs

To maintain—or better yet, improve—profitability, containing costs without hindering production is absolutely the name of the game for manufacturers. At the same time, connecting networks of plants and offices and deploying complex automations to improve workflow outputs are usually costly and time-consuming propositions, especially at the outset.

But a cloud-based communications and collaboration platform is an investment that pays off. In addition to the productivity and mobility gains measured, RingCentral customers say the platform helped them to shrink the costs of supporting their operations, with 25% reductions in IT spend, telecommunications costs, and hardware costs.

Setting a foundation for success

There’s no better organization for illustrating both the challenges and opportunities within the manufacturing sector than Foundation Building Materials. After a decade in business, the maker of construction materials such as drywall, stucco, and insulation had grown to serving 30,000 customers at more than 300 stores. But its legacy phone system was straining both productivity and profitability.

“As we crossed the 125, 150, 175-store thresholds, we were developing a growing mishmash of every type of phone solution you can imagine,” said Wasi Ahmed, Foundation’s Chief Information Officer. “We had different PBX systems, small VoIP providers at a few locations, and dozens of contracts with local telecom companies. It was such a mess, so complicated, that it took my team at least a week each month just to reconcile all of our communications invoices.”

Meanwhile, inconsistent call quality and reliability strained the organization’s ability to work together effectively across locations. While cost improvement and simplified IT support and billing were the primary drivers for switching to RingCentral, Foundation has seen significant operational benefits since making the switch. Improvements include better communication between employees across locations and faster response times to customers.

Get the stats

A closer look at the RingCentral advantage

In this #CustomerSuccess blog series, we take a closer look at the RingCentral advantage as illustrated by the survey results and explore some of the specific improvements seen across key business segments and within industry vertical markets.

Our latest Customer Success Metrics Survey included the opinions of manufacturing executives and decision-makers across 13 key metrics linked to the greatest challenges facing the sector today. To view the full results, download our survey datasheet for the manufacturing industry now.

Looking For Startup Consultants ?

Call Pursho @ 0731-6725516

Telegram Group One Must Follow :

For Startups: https://t.me/daily_business_reads