The only thing more dangerous than someone with disproportionately more confidence than competence is that same someone with a power tool.

Exhibit A: after an especially frustrating hour-long struggle to hang a curtain rod in a level manner, I thought long and hard about where things were going wrong. My process of holding the rod precariously against the wall with one hand, struggling to keep it straight while balancing a tiny plastic level, and painstakingly driving holes in the plaster with a cheap drill and even cheaper bit wasn’t cutting it.

Long story short: I bought a laser level, an impact driver, and better drill bits, and now the stuff I hang is consistently about 90% level if you don’t look at it too long—and I can do it in about a quarter of the time.

This is process optimization at its finest, and the same concept can be applied to great effect for your business.

Table of contents:

Quick review: What is process optimization?

Process optimization for businesses means identifying inefficiencies in regular procedures and fixing them to improve efficiency.

It may sound simple, but it can take a lot of time and expense to put into action. That’s why existing process optimization frameworks can help you find those holes in your business operations and patch them up, saving massive amounts of time and money that you can put toward more high-impact work.

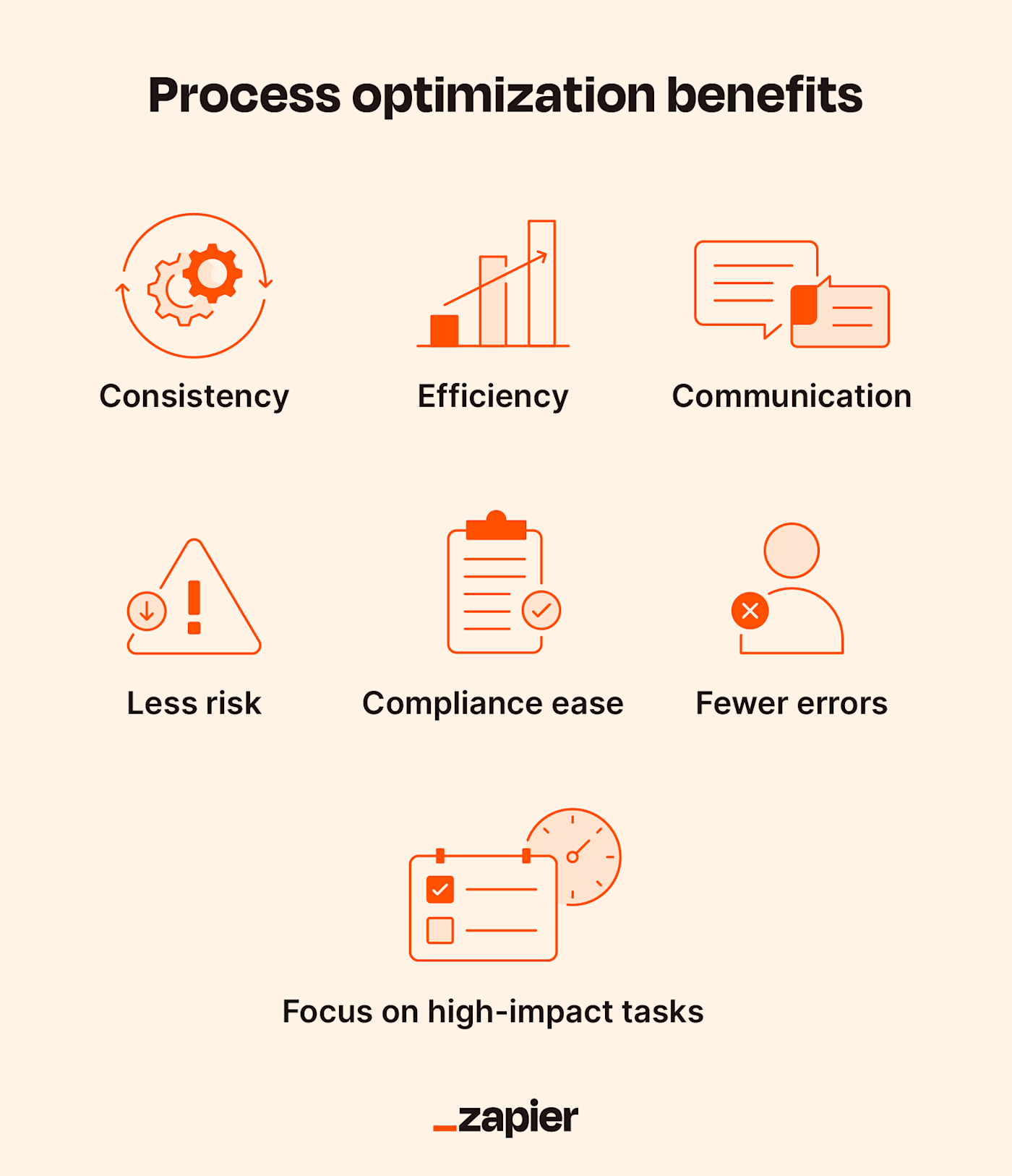

Benefits of process optimization for businesses

Whether it’s streamlining HR procedures, saving money, or automating lead generation, the ability to optimize business processes is something every business manager needs in their toolbelt. Keeping recurring tasks and complex procedures running optimally comes with a bevy of big benefits.

-

More consistency: Optimized processes have simpler procedures and are easier to replicate, leading to more consistent, predictable results.

-

Higher efficiency: Reducing redundancies, bottlenecks, and steps from recurring processes makes it quicker to get from start to finish.

-

Less risk: Through the optimization process, you can identify procedures that represent unnecessary risk and either remove them or apply extra precautions.

-

Fewer errors: Fewer steps and less complexity leads to fewer opportunities for human error.

-

More effortless compliance: Optimize compliance by streamlining monitoring and reporting procedures.

-

Better communication: Remove communication barriers between teams or build effective collaboration processes into workflows.

-

Greater focus on high-impact tasks: By cutting out repetitive, low-impact tasks, you free up time for team members to focus on tasks that are more worth their time.

9 business process optimization methods

If the process of “optimization” sounds vague to you, that’s because it is. Instead, you can use these established (and non-vague) optimization frameworks to identify and correct workflow hiccups.

1. Lean project management

No, I’m not talking about what my picture frames do. Lean is a general approach to project management that improves efficiencies and bottom lines by cutting waste. The broader Lean framework can encompass many techniques that can vary by industry, but specifically, Lean project management helps stop:

To get Lean, you’ll need to follow these five steps:

-

Step 1: Establish product value: What do your customers expect from your product? What do your internal team members expect from your operations? Once you can define the value expected of your product or process, you can strive to improve how you deliver it.

-

Step 2: Find waste in workflows: Starting at the most essential level, outline every step of every process required to go from initiation to completion, looking specifically for any of the wastes listed above. Value stream mapping is a useful tool here.

-

Step 3: Reconfigure workflows: Once you’ve found the waste points in your processes, create new workflows that cut them out.

-

Step 4: Respond to need: Whether this is an internal process for team members or an external one for customers, it should be led by the need of the end user. Creating a faster process that bottlenecks or begins stacking up excess inventory isn’t exactly Lean.

-

Step 5: Keep getting better: No process can ever reach perfection. Lean is an ongoing process that promotes continued improvement over time as people, trends, and markets shift. Keep looking for ways to cut waste, so you can keep driving value.

Process in action: A nature book publisher is looking for ways to reduce overhead. Their most popular titles are hiking guides, but demand ebbs and flows seasonally, and the market is price-sensitive. Through value stream mapping, they realize they can save money by cutting down on defective books and storage costs. They decide to offer their guidebooks as full-color digital eBooks at the same price and shift print production to on-demand while shifting from color to black-and-white. Books are only printed when someone orders them, and combined with eBook sales, they manage to cut production costs and storage costs without increasing prices.

Best for: Cutting waste in workflows, production, and other processes

2. SIPOC diagram

A SIPOC diagram creates a handy visual representation of your business processes. It helps decision-makers see the bigger picture and identify areas of opportunity for optimization, so they can better align them on the metaphorical wall. SIPOC stands for:

-

Suppliers: The sources of the resources (“inputs”) that influence the key outcomes (“outputs”) in a process

-

Inputs: The individual elements (whether a resource or an action) needed to execute the process

-

Processes: The steps required to run a task from start to finish using those inputs

-

Outputs: What you get as a result of the process, like a product, service, or action

-

Customers: Those who will receive, use, or engage with the outputs, including customers, partners, and internal team members

Process in action: The owner of a bakery looks at the viability of a specialty sandwich with a partnered butcher. They make a SIPOC diagram to identify the Suppliers (Bakery Owner, Butcher, Ingredient Supplier), Inputs (New Recipe, Specialty Meat, Supplemental Ingredients), Process (Sourcing Ingredients, Ingredient Prep, Cooking), Outputs (New Menu Item), and Customers (Bakery Owner, Butcher, Customers). They use the diagram to help streamline ingredient exchange and sandwich preparation, align budgets, and set a price point.

Best for: Gaining high-level understanding of a process

3. Process mining

Similar to data mining, process mining scrapes existing data to discover patterns, chart your current business processes, and back them up with real numbers.

Process in action: A healthcare provider uses data mining software to comb through logs of time-stamped events, including calls, appointment schedules, sent invoices, and paid invoices. Mining real data—including consistently updated current data—shows key points where scheduling and invoicing can be improved to improve patient retention and cut down invoice payment time.

Best for: Applying definite numbers to existing business processes for further analysis

4. Six Sigma

Originally devised for Motorola as a mathematical approach to quality control in manufacturing, Six Sigma is also a useful Lean technique for cutting down on waste, boosting accuracy and overall efficiency, and improving predictability. It can even be used in Agile project management. The name refers to how the rate of errors would only come with at least a six-standard deviation from the mean.

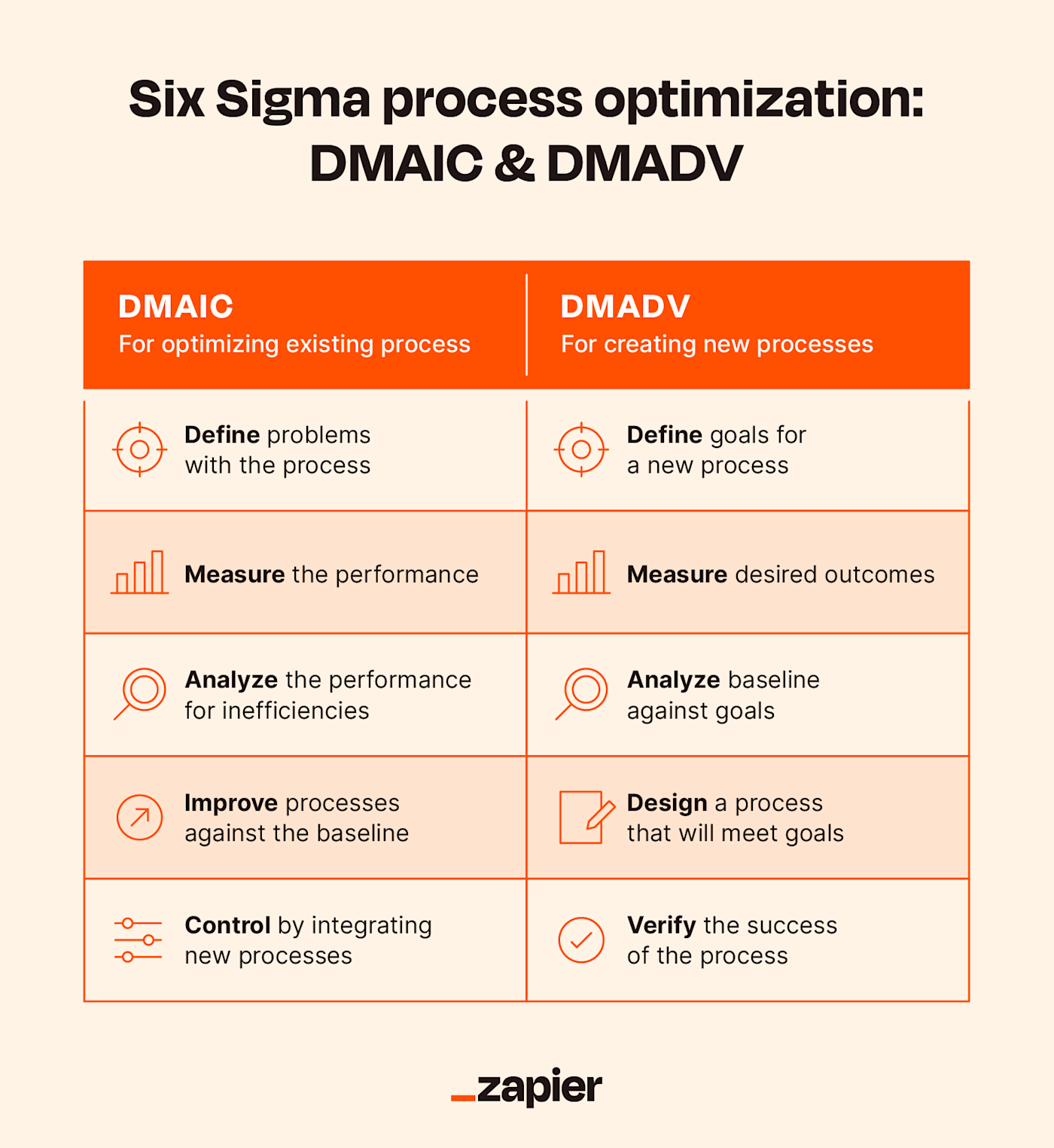

Depending on whether you’re looking to improve an existing process or create new ones, there are two acronyms you can use to apply Six Sigma: DMAIC and DMADV.

DMAIC

As a method for improving existing processes, DMAIC is broken down as:

-

Define: Start by defining the problem, goal, process, parameters, and customers.

-

Measure: Gather data to serve as a control to compare changes to later.

-

Analyze: Use the measurable data to find possible causes for inefficiencies or failures to reach goals you defined at the start.

-

Improve: Come up with strategies to solve for those inefficiencies or failures and execute them, noting improvements against your measured baselines.

-

Control: Put those strategies into practice by integrating them into your process going forward.

DMADV

If you’re creating a new process, you can apply Six Sigma through DMADV:

-

Define: Clearly outline your goals for this process.

-

Measure: Apply definite values to anything critical to quality (CTQ) for the customer, product, or process outcome.

-

Analyze: Based on the measurables and desired outcomes, come up with a design that will meet your requirements.

-

Design: Build out the process, and test it out before applying it to see if it meets your expectations.

-

Verify: Implement the process, and make sure that it’s aligning with your expectations, meeting goals, and staying within any limitations in practice.

Process in action: A printing company has to find a way to deal with increasing material costs for a price-sensitive market. Using DMAIC, they find that they can save money and increase revenue by updating their facility to cut down on printing defects.

Best for: Conceptualizing solutions for definable problems or designing new processes

5. Value stream mapping (VSM)

You can use value stream mapping to package a current process into a convenient flowchart. Like a SIPOC diagram, this Lean-friendly visual aid helps you see things as they are so you can find opportunities for improvement. VSM turns complex processes with abstract costs and resources into clear outlines with defined values.

To create a VSM, list each step in a given process. For each step, note the amount of time and any associated expenses required, along with whether it adds value (and if so, how much) for the end user. Once you can see the process laid out in clear values, you can design a better model that cuts out steps that take too long or cost too much to justify their value.

Process in action: A marketing company is looking to cut down on delivery times for their customers. A manager uses VSM to chart the production process from lead to delivery and finds that by restructuring their concept phase, they can streamline cross-department communication and 10 non-billable hours from every project.

Best for: Visualizing complex processes and finding wasteful steps

6. Five whys

Not to be confused with the five Y’s, five-wise, or the much more delicious Five Guys methods, the five whys technique for problem-solving trades theoretical decision-making for facts. Once you’ve identified a problem, the process is deceptively simple: ask “Why?” five times. It’s a strategy parents with toddlers know well and have likely worked hard to erase from their memory.

What makes this approach effective is that it forces you to stay grounded in facts and proof—you’re not responding with what might be happening; you’re responding with what did happen that caused the problem.

With every “Why?” you answer, you get closer to the core of the problem. Once you have a specific answer, ask why that answer is true. Repeat until you arrive at the final matryoshka doll of an answer. Fixing that final problem could solve the broader issue you started with four whys before.

Process in action: Sales of a productivity app were underwhelming during the developer’s back-to-school sale. They use the five whys to find a likely reason students wouldn’t follow through on a free trial signup. Why #1: Signups for the free trial were low. Why #2: Conversions on the landing page were low. Why #3: Many users abandoned the signup process. Why #4: Over 60% of users left after the first page of the signup form. Why #5: The second page of the signup form required credit card information. They decide to cut the credit card input requirement and redeploy the campaign later in the semester.

Best for: Finding the heart of a complex problem

7. 5S

Not to be confused with the five Y’s—a term I made up in the last section—5S is a practical Lean model that creates more efficient and orderly physical workspaces. Each “S” is based on a Japanese term that conveniently also starts with an “S” sound.

-

Sort (Seiri, 整理): Separate necessary and unnecessary items, and get rid of anything not needed for current processes.

-

Set in Order (Seiton, 整頓): Once you’ve whittled down to only the items you need, organize them, so they’re easy to find and use at all times.

-

Shine (Seiso, 清掃): Give your newly organized space (virtual or physical) a deep clean to set a new baseline.

-

Standardize (Seiketsu, 清潔): Continue keeping the space clean by hiring professionals and/or rotating specific duties internally.

-

Sustain (Shitsuke, 躾): Establish a plan for maintaining your bright, shiny, orderly new office’s new baseline going forward.

Process in action: After moving into a new space, a growing startup company quickly fills it with new gear, new workstations, and new hires. They get rid of outdated equipment (Sort), stock a newly empty closet with office supplies (Set in Order), hire a cleaning company to do a deep clean over the weekend (Shine), schedule cleaners to return every week (Standardize), and implement biannual “stuff audits” to keep the clutter down (Sustain).

Best for: Creating an orderly working environment

8. Plan-Do-Study-Act (PDSA)

Sometimes referred to as PDCA (replacing “study” with “check”), Plan-Do-Study-Act is a Lean method for gauging the effects of a change. This won’t help you find new solutions or identify problems, but it does the important work of proving whether your process optimization solutions have the desired effect. Here’s the four-step process:

-

Plan: Clearly define a specific problem, measurable goals relating to that problem, a specific change to address that problem, and quantifiable metrics that can prove the effectiveness of that change. To super-charge this step, combine with five whys (to home in on the problem) or a SWOT analysis (to specify goals).

-

Do: Put your plan into action. Since the point of this process is to prove the efficacy of a change, mark a performance baseline to compare outcomes to later. Then, decide on a timeline and continue recording data until there’s been sufficient time to see measurable results from the change.

-

Study: At the end of your timeline, compare the performance since the change was implemented to your baseline. Refer back to your earlier goals, and see if your change has had the effect you were hoping for.

-

Act: If your change successfully solved the problem outlined in Step P, congrats! Integrate that change into your ongoing processes. If the change didn’t fix the problem, start the process over again with a new solution.

Process in action: A travel company is seeing lower open rates on their marketing emails and wants to ramp up engagement with summer approaching. They decide shortening subject lines and adding emoji may help increase open rates, aiming for at least a 15% improvement (Plan). Over three months, they A/B test by segmenting half their contact list at random to receive the same emails but include longer, text-only subject lines for Group A and short subject lines with emojis for Group B (Do). After three months, they notice 23% higher open rates for Group B (Study). Going forward, they set subject line guidelines for a shorter maximum character count and make it policy to include at least one emoji for all marketing emails (Act).

Best for: Proving the effectiveness of a specific change

9. Total Quality Management (TQM)

True to its name, Total Quality Management takes a holistic philosophy for improving performance, deliverables, and/or customer experience by finding and correcting issues and empowering employees. TQM is an ongoing process that cuts down on errors, improves efficiency, and ensures employees at all levels have the resources they need to execute. When implementing TQM, there are a few general guiding principles to keep in mind:

-

Quality improves continually: What “quality” refers to can vary by business, but you can look to your customers’ expectations to gauge this. At the end of the day, they’re the ones deciding on whether your product or service meets value expectations.

-

Quality improvement is everyone’s responsibility: TQM holds everyone in an organization accountable for success. Non-management employees should be properly trained and outfitted to perform all of their essential functions, and management is responsible for identifying gaps in training and resources—and then addressing them.

-

Quality improvement is an ongoing process: You can’t expect to achieve perfection, but you can expect to get better over time. TQM isn’t a one-time solution as much as a philosophy for continuous improvement and refinement.

-

Quality improvement should be provable: If you want to continue improving, you need to be able to show progress. Apply quantifiable metrics to specific attributes of your product quality, set goals, and make targeted changes that help meet KPIs.

Process in action: An edtech company is losing ground to key competitors on similar software with greater functionality and a similar price point. Guided by TQM, they perform a full audit of every department to find internal growth opportunities. Management teams attend seminars on process optimization, sales teams get monthly training from external professionals, marketing teams are given a budget to overhaul the website, and product teams meet with college instructors to learn how their product can be changed to better meet customer needs.

Best for: Creating a framework for continuous improvement

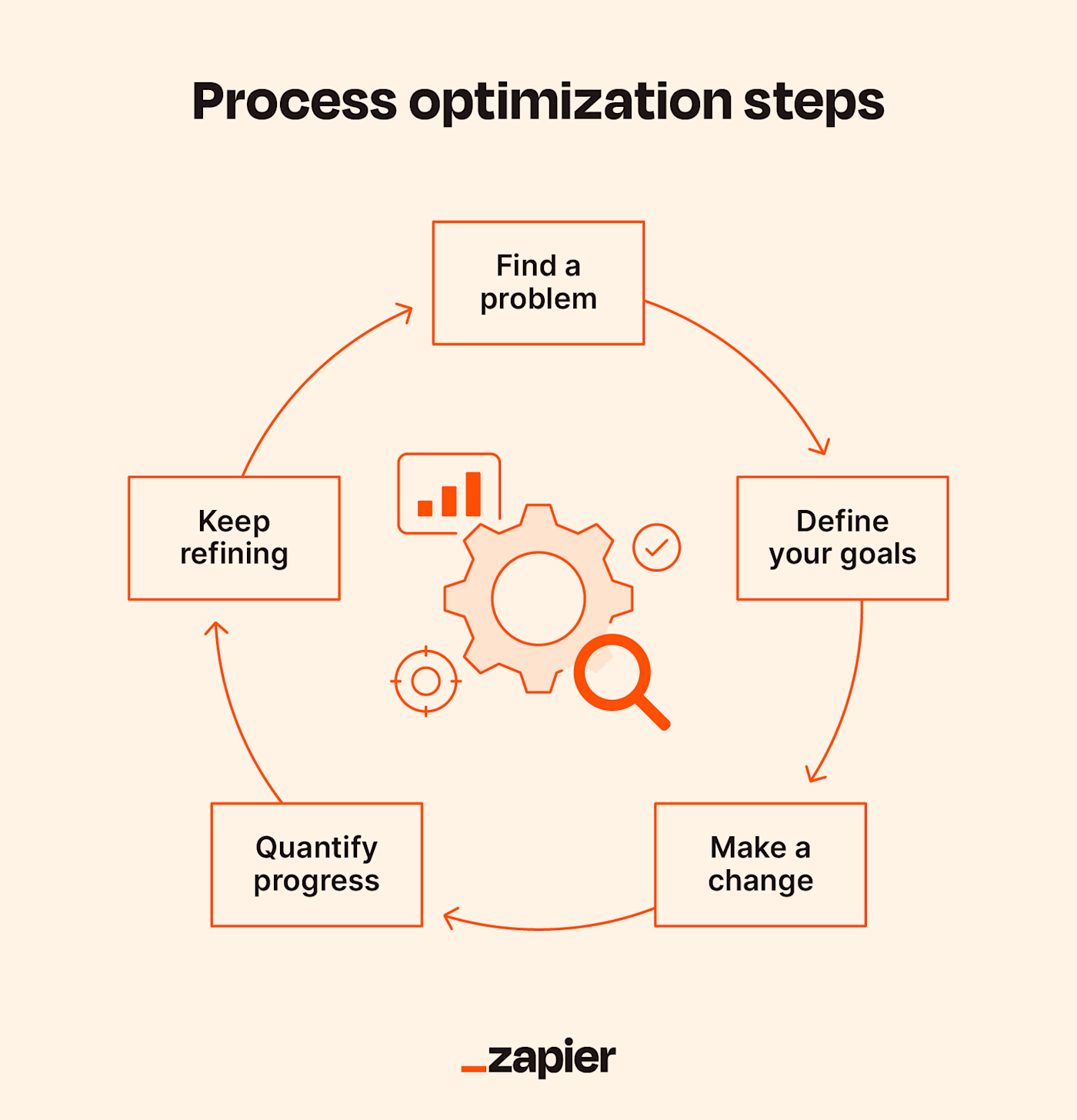

Executing optimization in 5 steps

No matter which of these process optimization techniques you choose to explore, there’s a pretty general overarching structure to process optimization you can expect to work through:

-

Step 1: Find a problem: You can’t get better if you don’t know where things are going wrong. Process optimization starts with being specific about the problem you need to solve.

-

Step 2: Define your goals: “Better” isn’t a specific enough end goal. Even if you can’t expect to create a flawless process, you can set achievable, quantifiable goals that prove your progress.

-

Step 3: Make a change: Take steps toward your optimization goals by making incremental changes that lead you from problem to solution.

-

Step 4: Quantify progress: Apply analytics to your changes so you can monitor your progress toward your goals and see how effective your optimization efforts are (or aren’t).

-

Step 5: Keep refining: If one tactic doesn’t work, try again. If it does work, integrate it and start looking for the next inefficiency.

Process optimization software

Software can make process optimization tactics both easier to implement and easier to adopt. From task management to visualizations to automation, these solutions can help you simplify, streamline, and cut waste—so your team can focus on high-impact work.

-

Kanban: These apps help you refine workflows by breaking them down into boards, lists, and cards, all in one clear dashboard.

-

Project management: If you juggle countless projects over multiple departments, you can use project management apps to organize your processes and streamline cross-team collaboration.

-

Flowcharts and diagrams: Optimization gets much easier when you can see your processes mapped out. Use visualization software to create flowcharts, diagrams, and other visual aids that lay your processes bare so you can find pesky bottlenecks and unnecessary time-suckers.

-

Automation software: There’s nothing more optimal than automatic, and automation software can streamline work across departments. You can use Zapier to bring automation to all your workflows by connecting all the apps your company uses.

Zapier is a no-code automation tool that lets you connect your apps into automated workflows, so that every person and every business can move forward at growth speed. Learn more about how it works.

Like home improvement, process optimization is never-ending. In a house, there’s always another wall to paint, another piece of furniture to replace, a crack that needs filling, a mirror that needs hanging—the same is true of any business and organization (metaphorically speaking). The key is to always be working toward better, more efficient workflows and procedures through smarter workflows, insightful analytics, considered changes, and—ideally—automation.

Related reading:

[adsanity_group align=’alignnone’ num_ads=1 num_columns=1 group_ids=’15192′]

Need Any Technology Assistance? Call Pursho @ 0731-6725516